Vandex Waterproofing...

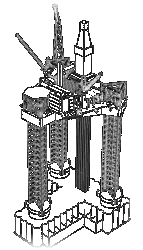

Gravity Base Tank

The gravity base tank of the ultra modern North Sea Oil Rig for the harding field is the largest concrete structure ever built by BP. The cellular oil storage tank with its immense 120m x 115m x 34m dimensions forms the base of the rig. Built using a specific ratio of lightweight aggregate concrete and prestress techniques to anticipate various loads and achieve defined floating, the huge reinforced concrete structure comprises 80 oil tanks joined in cellular fashion and holds 500,000 barrels of crude overall.

Having wall thickness of 400mm the reinforced concrete tanks feature a common slab 850mm thick and roof slabs of 900mm thickness. The entire reinforced concrete structure comprises 35,000 m3 of concrete, 17,000 tons of rebars and 1000 tons of prestress cable.

The complex building procedure including the dry dock activities through floating to location and lowering to the ocean floor exposes the structure to extreme loads. To meet the particular loads induced during building, transporting and installation, a flexible concrete coating was prescribed as additional waterproofing for high stress zones.

Building materials intended for the crude tanks were field tested by the test laboratories of Taywood Engineering in London.

The Vandex product also went under rigorous testing including permeability tests on both the positive (at water pressures of 110m) and negative sides. Vandex BB75E was also subjected to crack bridging tests at 110m water pressures.

Taywood engineers chose Vandex BB75E and Vandex Super for the exernal walls in the transition zone from the slab to the rising walls of the crude tanks. In the areas where calculations indicated a likelihood of cracks Vandex coatings were also used.

for the BP Harding Field