Concrete Mix...

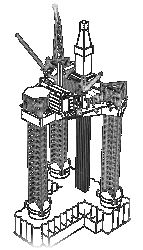

Gravity Base Tank

As the structure would not be subject to any significant early age loaing the strength requirements were specified for 56 days rather than the normal 28 days. this allowed the use binder with slow hydration and low heat generation. A blended Portland cement and pulverised fly ash was chosen. For the LWA sintered fly ash from Boral Lytag was selected. For the fines a blend of Lytag with natural sand was used.

To keep down the density of the concrete the project decided to batch the LWA in a semi dry condition. The average moisture content of the LWA and fines was 3% and 5% respectively. Super plasticisers were used to help achieve the necessary workability. With time there was a reduction in workability as the aggregates absorbed some water after batching and before the initial set. From the initial colapse slump (60cm spread) the slump declined to about 10cm after two hours. It was found possible to control workability to suit the conditions from summer to winter, and for large slab pours and slip form walls.

The mix compsosition for slip formed parts of the structure was

for the BP Harding Field

| Cement CEM I | 380 kg/m3 |

| Pulversised fly ash | 160 kg/m3 |

| LWA Lytag 4/12mm | 730 kg/m3 |

| LWA Lytag 0/5mm | 200 kg/m3 |

| Natural Sand | 200 kg/m3 |