Harding Oil Field...

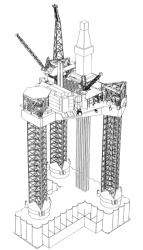

Gravity Base Tank

The Harding field lies some 320km north east of Aberdeen and covers an area of some 20 square km in Block 9/23b. Commercial quanties of oil were first discovered in early 1988 and following this discovery a 3D seismic survey and 20 appraisal wells were carried out. the field has estimated recoverable reserves of 185 million barrels of oil and some 200 billion cubic feet of associated gas. The harding field is operated by Bp who have 70%, Repsol 25% and Ranger 5%. The depth of the water is 110 meters and the first oil was produced in late 1995.

Harding has been developed in line with the CRINE (cost reduction inititive for the new era) inititive. a small project team has provided leadership, alignment of objectives and co-ordination between the contractors involved in the design and fabrication of the platform. Extensive efforts has been made to simplify the processes and extract unnecessary costs by using propriety designs and simple specifications. as a result these efforts harding is one of the lowest cost field developments currently underway in the north sea.

The Harding resovoir is an Eocene submarine-fan type structure lying some 2,000 meters beneath the sea. the filef will initially be developed from two pools of oil, harding central and south. a total of 16 wells will be drilled, 9 of which will be horizontal production wells and the remaining 7 wells will be used for water and gas injection/lift to maintain pressure and maximise recovery.

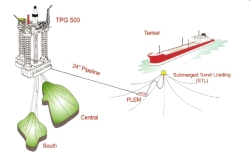

Field life is expected to be around 20 years with peak oil production of around 60,000 barrels per day. Associated gas will initially be re-injected into the resovoir with exports not commencing until oil production is in decline. Produced oil will be stored in the fields gravity base prior to export via shuttle tankers.

Fluids from the producing wells join up at a production manifold and from there they are carried to the process plant. A three stage seperation system spperates water and gas from the oil. The stabalised crude is then transfered to the concrete gravity base for storage. Dynamically positioned oil tankers will viist the field on a regular basis and once a tanker has been connected to the tanker loading system oil will be pumped from the platforms base into the tankers. the loading operation would take 24-30 hours.

Once seperated from the oil and water, gas is dehydrated and compressed. A portportion is used as fuel for the platforms 13.5 megawatt gas turbine driven generators and the remainder is used for gas lift or reinjection into the resovoir.

Produced water from the seperators is routed through hydrocyclones to the water being reinjected into the resovoir to assist in maintaining resovoir pressure

The shallow and complex nature of the harding resovoir posed problems as it was initially envisaged that a large number of development wells would be required, but advances in extended reach and horizontal drilling technology led to a development propsal based on:

A heavy duty triangular shaped jack up drilling and production unit placed between the two oil accumilations

An 84,000 ton concrete gravity base capabile of storing 580,000 barrels of oil.

A 2km 34in diameter pipeline to a tanker loading system

for the BP Harding Field

Click on an image to enlarge